Services

The experiments conducted on our components and the study of our products in static and dynamic conditions have allowed us to guarantee the maximum reliability of our products, containing prices and responding to the continuous evolution of the market.

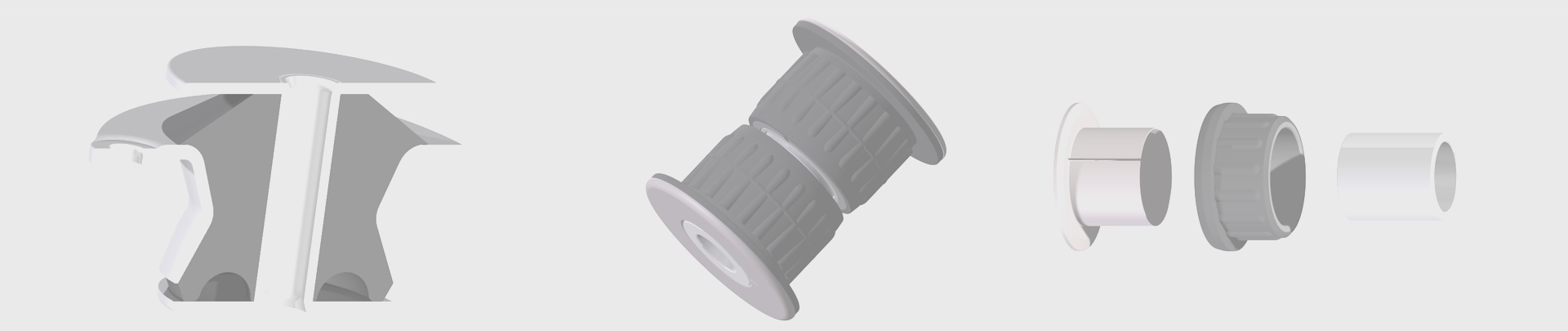

Design and engineering

The experiments conducted on our components and the study of our products in static and dynamic conditions have allowed us to guarantee the maximum reliability of our products, containing prices and responding to the continuous evolution of the market.

Most of our products are developed to precise customer specifications. Our key strengths include our speed of response, high quality standards and the ability to find bespoke solutions even in the case of small scale productions.

We carry out a preliminary feasibility study during the design and engineering phase, after analysing all the requested characteristics.

We then perform a simulation to calculate the stress of the rubber following the application of a load to define the shape and the type of materials to be used.

We then design and manufacture prototype moulds and produce the first samples on which we perform the first validation tests and – if necessary – the fine-tuning of the materials, in particular the compound.

Once all the characteristics have been defined, we design and manufacture the standard equipment and the subsequent parts on which all the tests necessary for the qualification of the product will be carried out.

Testing

The R&D and Quality departments carry out examinations and surveys on the many parameters of the materials we use for our products.

The following are some of the tests we perform:

- IRHD hardness;

- Micro IRHD hardness;

- Rheometric curve;

- Axial failure load diagrams;

- Radial failure load diagrams;

- Torsional failure load diagrams;

- Conical failure load diagrams;

- Hysteresis curve calculation;

- Destructive rubber metal adhesion tests;

- Non-destructive rubber metal adhesion tests;

- Fatigue tests in various frequencies and on different axes.

We are also able to test finished products and customer assembled components such as leaf springs, suspensions and stabiliser bars.

In the case of tests requiring specific equipment, we outsource these tasks to qualified independent laboratories with whom we have been working for years.